|

| Image credit: NASA |

Apart from Bell-nozzle engineers have also tried a different

type of nozzle known as Aerospike Nozzle. Although this concept was never

implemented on a real rocket, in 1997 NASA tested this nozzle on SR-71

aircraft.

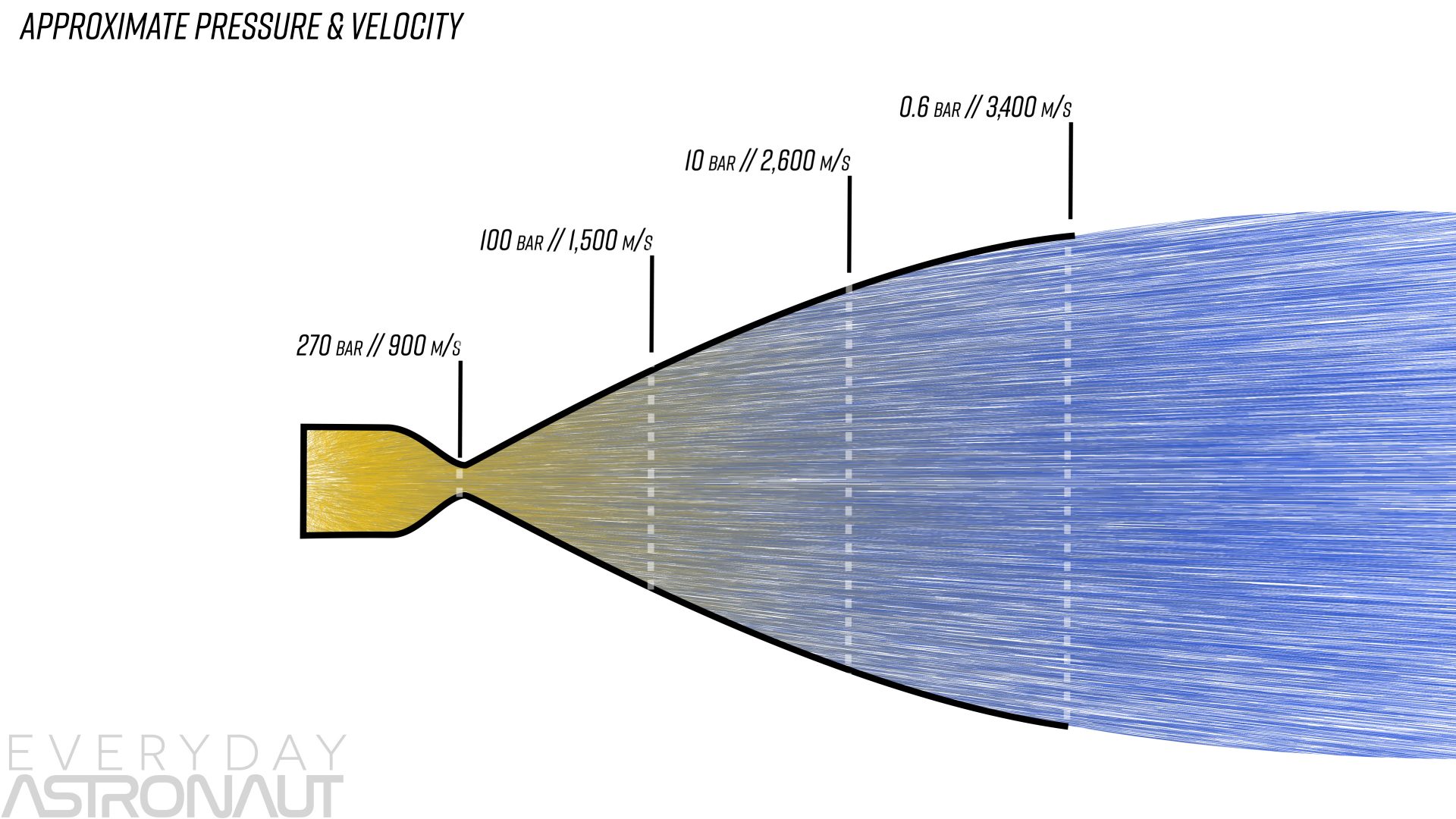

To achieve this a

bell-nozzle uses a convergent-divergent nozzle. The convergent section

increases the velocity up to sonic speed (Mach 1) and the divergent section

increases the velocity above sonic speed (supersonic) (> Mach 1). This helps

to achieve maximum exhaust velocity by decreasing the pressure. Now you might be wondering why am I using the

term “local atmospheric pressure”. Well, the reason for that is as a rocket climbs

in altitude the atmospheric pressure decreases. So, while designing the nozzle

engineers have to take this decrease in pressure into account.

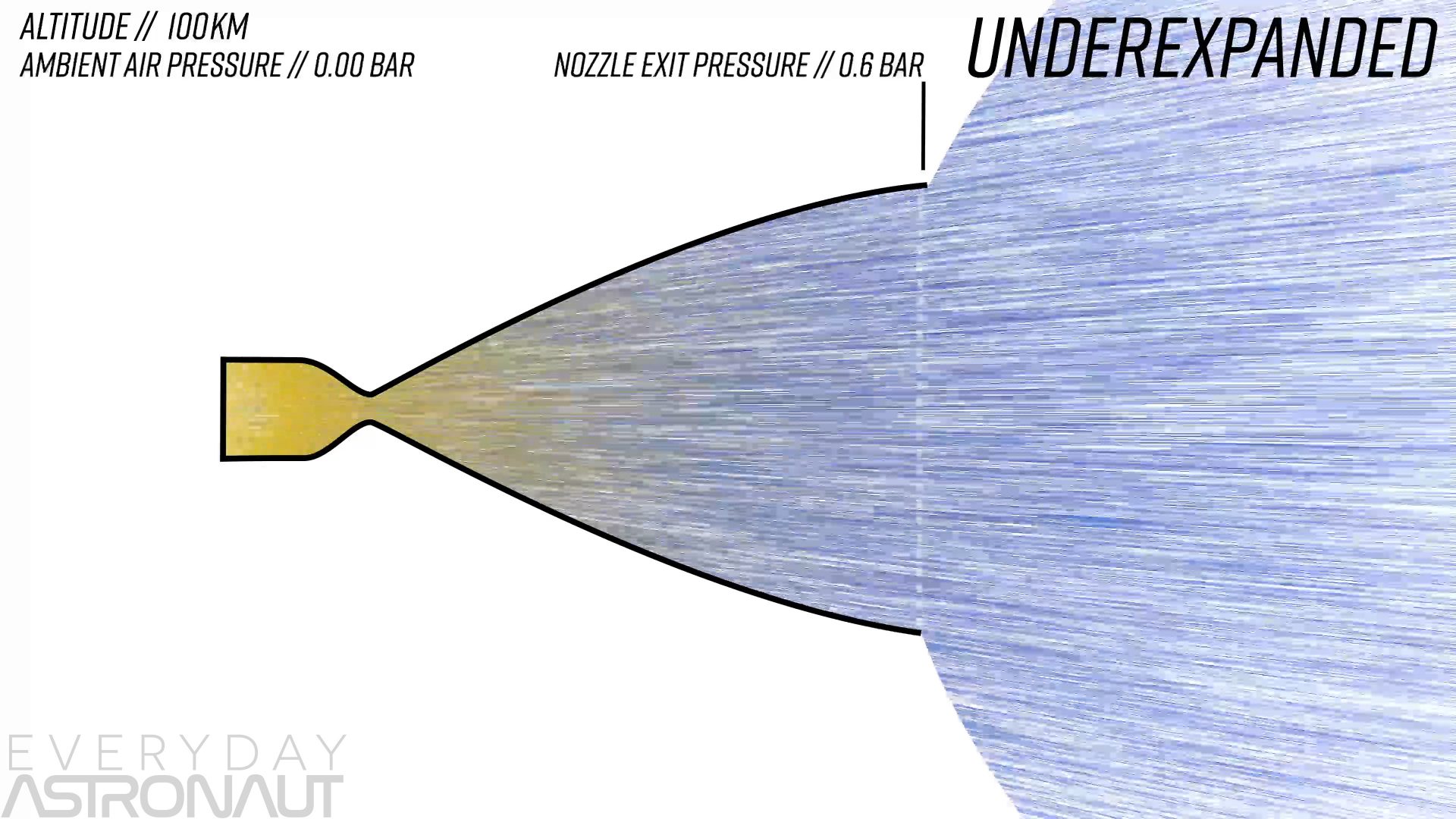

If a nozzle is designed just for the sea level pressure, then at high altitudes the exhaust gases will spread out while exiting the nozzle decreasing the thrust produced by the engine, known as the Under-expanded nozzle. This situation becomes even more extreme in a vacuum. This is one of the reasons rockets are designed in stages.

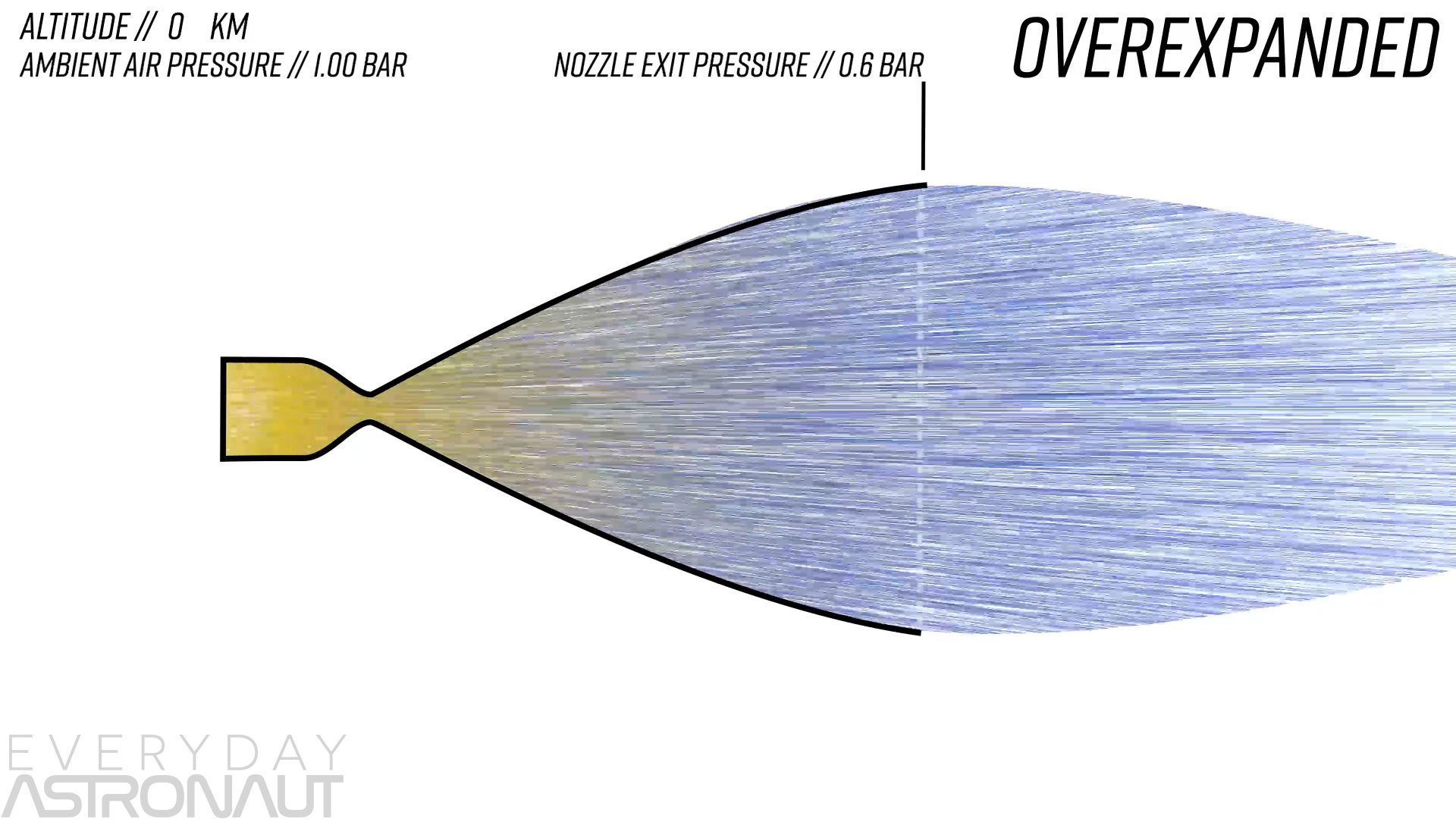

For a nozzle to produce maximum rated thrust the exhaust gases should exit the nozzle perfectly straight. When the nozzle is too big to decrease the exhaust gas pressure below the atmospheric pressure, it is known as an Over-expanded nozzle. For the nozzle to work on vacuum (space) it needs to be of infinite length, which is impossible to do. To deal with this engineers settle for a middle ground.

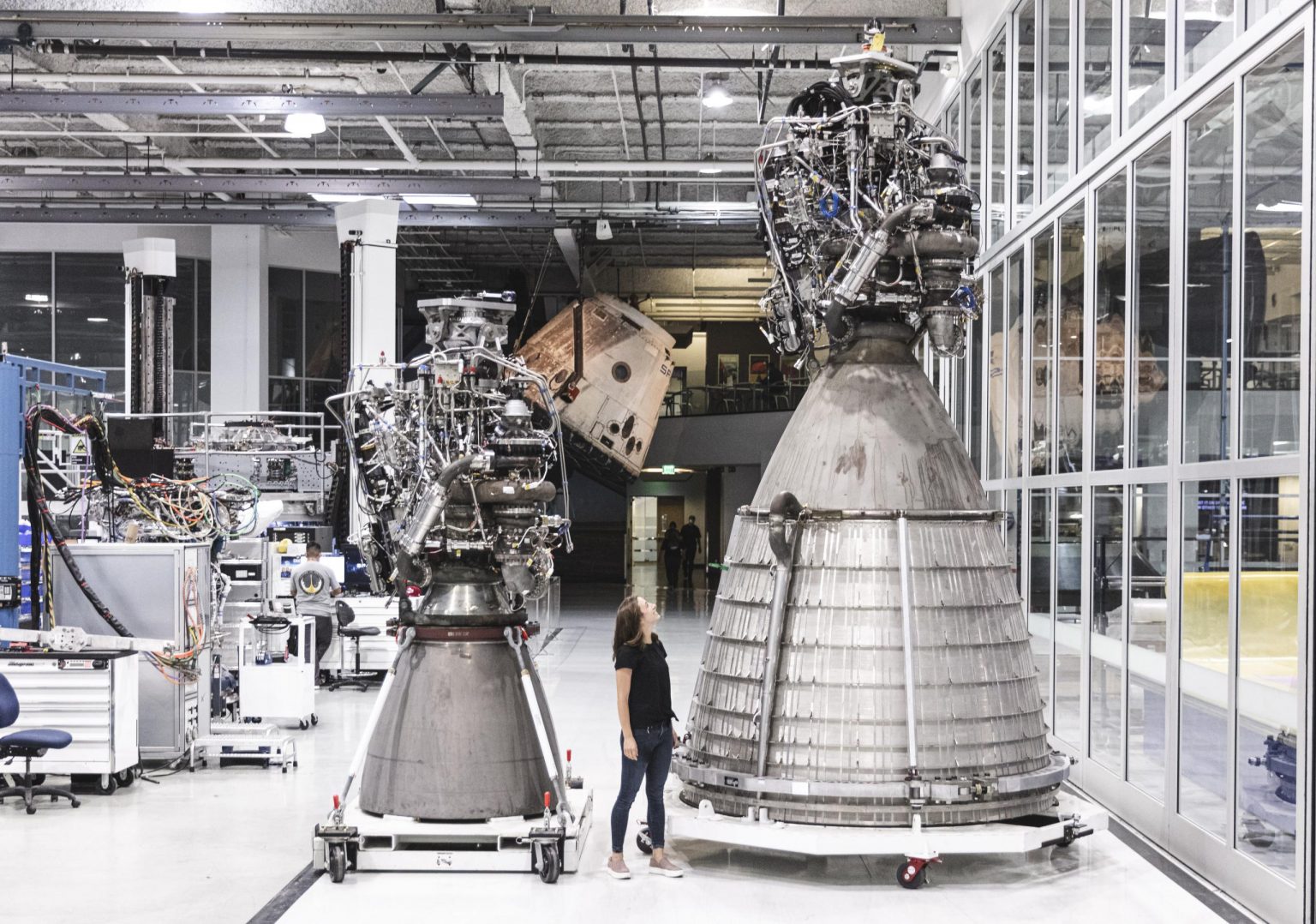

Below you can see two engines with different nozzle sizes, the small one (Space X Raptor Engine) is for operation in earth's atmosphere, and the big one ( Space X Raptor Vacuum Engine) is for operation in space (vacuum).

|

| Image credit: SpaceX |

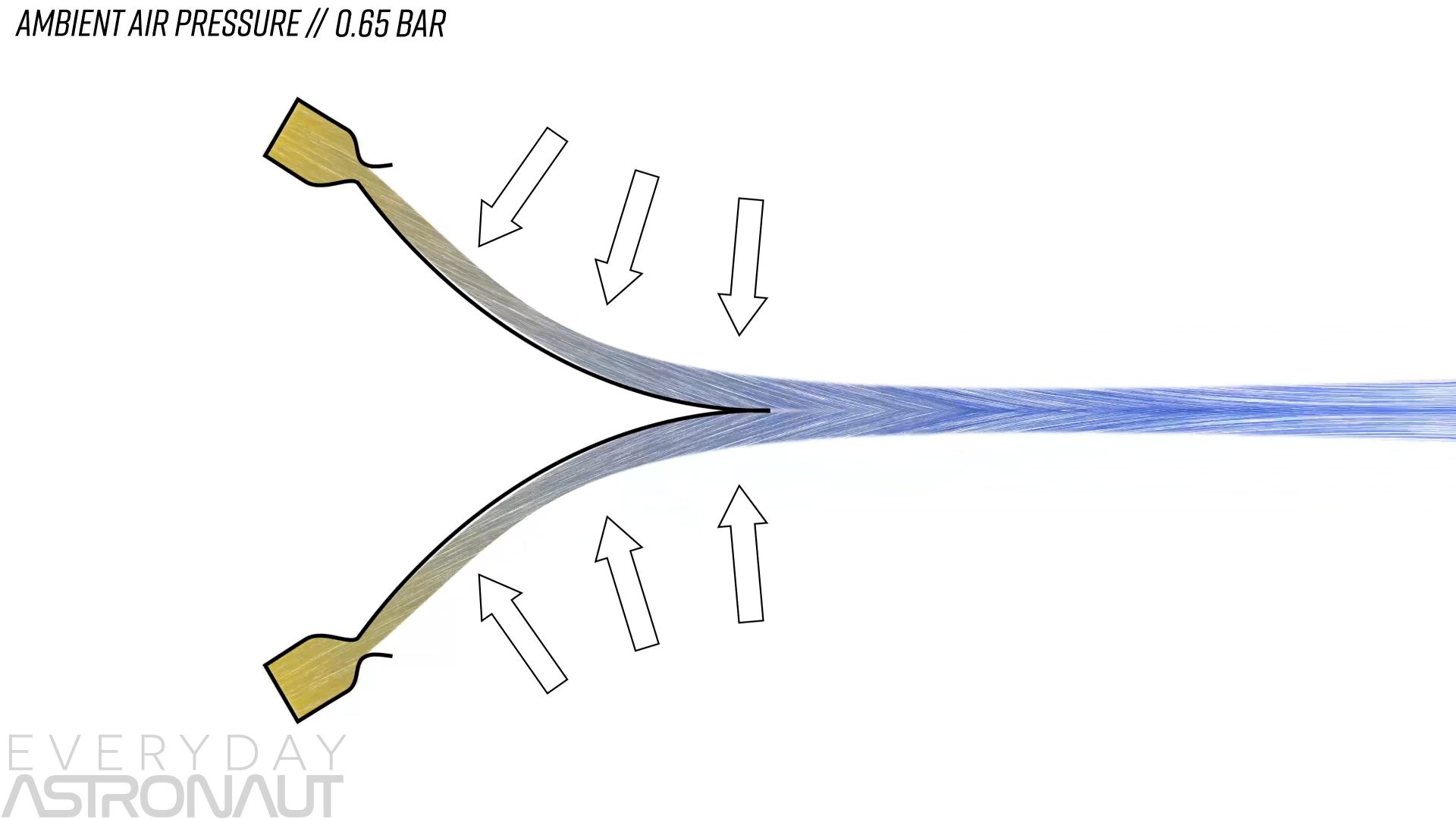

Now that we understand how does bell-nozzle works let’s see

the working of the Aerospike nozzle. Aerospike nozzle can be used in both

atmospheric conditions as well as in vacuum. It is just a bell-nozzle which is

cut in half and then arranged side by side. In this, the atmospheric pressure

acts on the exhaust gases and pushes them into the wall of the nozzle which

makes flow separation impossible. There

are two types of aerospike engines, Linear Aerospike and Toroidal Aerospike.

One advantage that the aerospike engine provides is the use of only one stage in a rocket which can operate from sea level to vacuum (space). This is very useful for space shuttles which have to work both in atmospheric conditions as well in vacuum. So despite this why aren't we seeing rockets with aerospike engines?

Looking at the fact that aerospike engines can be used in

both atmospheric conditions as well as in a vacuum, makes them ideal for rockets

as we don’t have to put multiple stages or at least aerospike engines would be

a much better choice for the first stage of a rocket as it has to operate in

both conditions. Well, we have looked at the advantages of aerospike engines

now let’s look at its disadvantages.

Aerospike engines have two main disadvantages, heat and

weight. The exhaust nozzle of a rocket engine has to operate at a very high

temperature which can melt the material used to make the nozzle. To prevent

this various cooling systems are used to keep the nozzle from melting away. Aerospike

nozzles have a much larger area to cool as compared to bell nozzles. To

dissipate the heat in the aerospike nozzle, multiple cooling techniques might

need to be used or we might have to use materials with a much higher melting

point. Both of these methods are expensive and reduce the performance of the

engine.

Aerospike engines also have a low thrust-to-weight ratio, because of their large combustion area, additional fuel feeding system which it requires and additional support structures.

Despite all the disadvantages of aerospike engines with

ever-evolving technology around us, we might one day see an aerospike engine

used in an actual rocket/spacecraft.