Well apart

from their striking appearance on some aircraft such as the Airbus A350, these

winglets serve a very specific and important function which saves airlines

millions of dollars on fuel. To understand the purpose of winglets we first

need to understand the concept of Induced Drag.

Induced

Drag

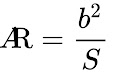

To understand induced drag we first have to understand how

the wings of an airplane produce lift. Wings generate lift by creating a low-pressure

region above the surface of the wing and a high-pressure region below the

surface of the wing. These high- and low-pressure airflow meets at the trailing

end of the wing where the high-pressure airflow tries to meet with low-pressure

air flow, creating vortices. These vortices are much stronger at the wing tip

and their strength reduces towards the root of the wing.

|

| credit: Real Engineering[YouTube] |

In the right atmospheric conditions, you can see these

vortex lines generating from wingtips. These vortices produce a downwash which

reduces the effective angle of attack (α) of the wing. You can see in the image

below how the effective angle of attack of the wing is reduced. Since lift acts

perpendicular to the relative airflow, and because the relative airflow is at

an angle, lift is also slightly tilted backward. We can now divide the lift

into two components.

|

| credit: Johnwalton |

The vertical component has to balance the weight of the

aircraft and a horizontal component which is our Induced drag. As we can see

the direction of the induced drag is backward, it is resisting the forward

motion of the airplane which results in more power required to move the

aircraft forward. Since induced drag is produced because of lift it is also

known as "drag due to lift". Hence

if we want to increase the efficiency of our wing we have to reduce induced

drag as much as possible.

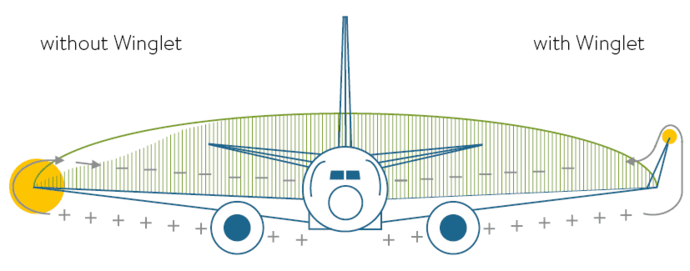

Now let us see how the design of the wing affects induced

drag. The coefficient of drag for induced drag is inversely proportional to the

Aspect Ratio of the wing i.e. more the aspect ratio less the induced

drag. Aspect ratio is the ratio of the square of wing span to its area. So, if

we want to reduce the induced drag, we have to increase the wing span as much

as possible.

The equation for induced drag is:

b = Wing span, and

S = Aerea of the wing.

By the above-mentioned formula, we can also conclude that as

we increase the angle of attack the CL, which is co-efficient of

lift, will also increase and this will result in an increase in the induced

drag. By this equation, we can conclude that if the lift increases the induced

drag will also going to increase. This further concludes the fact that it is a lift-induced

drag.

Wing

Design

One

solution to reduce induced drag is to increase the wing span as much as

possible. But designers can only increase the span up to a certain point, after

that, it will be impossible to accommodate the aircraft in the airport. So,

designers have to find a different solution.

One

such solution is to install wing-tip devices on the airplane wing. The earliest

concept of such wing-tip devices is developed by an English engineer Frederick

W. Lanchester. He patented the wing end-plate which was installed in the

wing-tip and helps to reduce the wing-tip vortex.

Today

most modern airplanes use a type of wing-tip device called “winglets”.

These were designed by Richard T. Whitcomb in the 1970s at NASA LangleyResearch Center, What motivated the development of winglets was the rising

oil prices in the 1970s which forced aircraft manufacturers to make aircraft more

fuel efficient.

Effects

of Winglet on Induced Drag

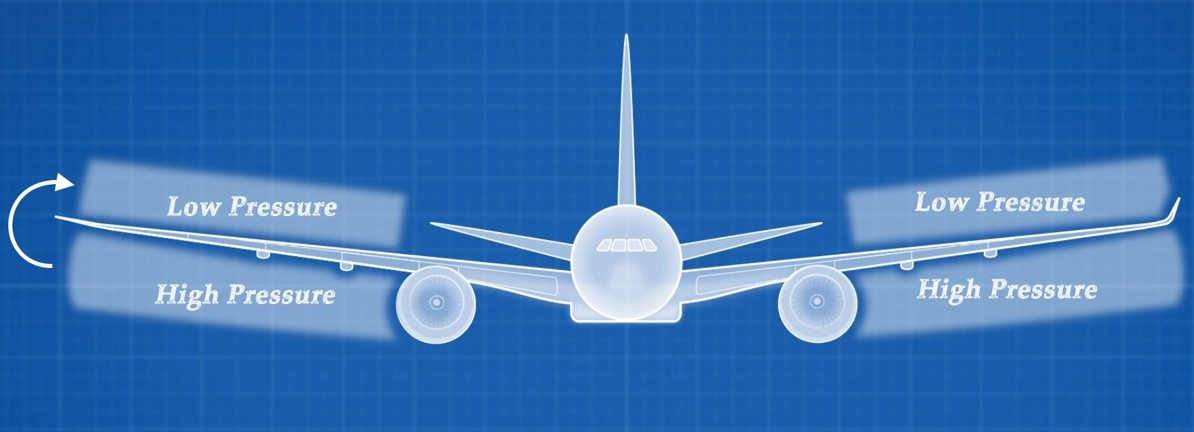

As

we discussed how the induced drag is formed when the air from the high-pressure

region (below the wing surface) tries to go to the low-pressure region (above

the wing surface). To stop this movement of air winglets are used. As you can

see in the image below how the wing without winglet airflow can easily travel

from the high-pressure region to the low-pressure region creating a large

vortex. While in the wing with the winglet, the vortex which is formed is much

smaller.

|

| credit:www.facc.com |

As

a result of this induced drag is decreased and lift distribution over the wing is

more optimum. Aircraft manufacturers can achieve fuel efficiency of 4-6 percent

by using winglets. Winglets also help to reduce the wake vortex produced by the

wing which helps to increase the frequency of take-off and landing of aircrafts

on airports.

As

there is no single wiglet that fits on every aircraft, winglets come in a

variety of shapes that differ from one aircraft to another.

Raked Wingtip

I

talked about winglets up until now but if you have seen the latest Boeing

jets like B777 and B787 you might have seen that they don’t have a winglet at

their wingtip. Boeing uses something called a Raked Wingtip. These types

of wings have larger sweeps at wingtip as compared to the rest of the wing.

|

| credit: Yoshiharu Mohri |

As

you can see in the image the raked wingtips are much narrower than the rest of

the wing. This results in decreased average chord length of the wing. This

design helps to increase the wing span with a very small increment in the wing

area. Due to this the aspect ratio

of the wing increases and induced drag decreases.

Raked

wingtips are more efficient than conventional wingtip devices. Recently Boeing

has developed a new version of the B777 family called Boeing 777-X which has

folding wingtips. The reason to have a folding wing structure is to increase

wing span while flying at the same time not taking any more space in the

airport than previous versions of B777 as wingtips can fold while in the

airport terminal.

|

| credit: Jon Ostrower |

This

blog is just a simple explanation of how Winglet works if you want to read

about them in more detail, I recommend you to follow the below links.

1. https://www.grc.nasa.gov/www/k-12/VirtualAero/BottleRocket/airplane/induced.html

2. https://www.facc.com/en/BEyond-Blog/Flying-better-Winglets

3. https://www1.grc.nasa.gov/beginners-guide-to-aeronautics/winglets/

Thankyou! Very much for reading. I hope you learned something new. Stay curious!